When purchasing a CNC Router Table, many models will offer a table or stand for an additional price.

In this article we show you how to build your own table out of materials from your local lumbar or big-box store.

We will outline how to make your own simple, inexpensive yet effective, homemade CNC machine stand.

- Start by cutting two 45’s on the 4×4 legs.

- Then drill holes and pound 5/16 tee nuts into them.

- Then use carriage bolts which allow you to level the table.

- 1×4’s complete the frame and MDF provides a nice smooth surface to support the machine.

With an aluminum machine stand with a shelf that fits all CNC routers from the Galaxy and GX series and other comparable sizes, you can operate your CNC router more conveniently.

This durable custom designed CNC stand has a built in shelf for quick access to your control units and accessories.

Made of rigid aluminum, this sturdy stand can take a beating.

Choose your size, type of feet, and optional Keyboard/Monitor/Mouse arm.

Live Shop

Replacing a unique molding

From Adam:

Hobbyist here who is restoring an old home and wants to make trim to match some of the existing trim in my house.

I haven’t found any trim profiles to buy that match.

Thinking about making my own trim. I haven’t found a router bit that matches the profile.

How easily expensive are these to get made? I have a large router. I don’t have a shaper or a molding machine.

What are your thoughts on trying to get a bit made? Other options I should consider?

I’ve seen a blade for a table saw that you attach knives to. Has anyone done this?

Article on running big moldings

Made You Look: Custom sanding blocks

How to Create Custom Moldings with Handplanes

Built-Up Moldings

CNC Router Table joinery

From Nathaniel:

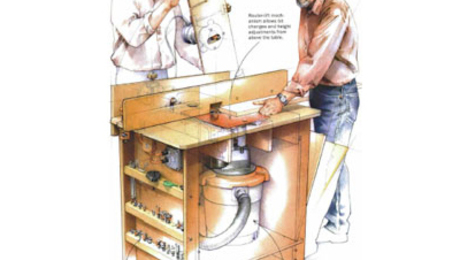

Having recently used a router table for the first time,

I began to imagine some brilliant possibilities for making joinery that I haven’t seen covered on the usual sources (YouTube, Google, etc).

I’m beginning to fear the reason for this is that the methods are perhaps unsafe.

Before I risk digits finding out for myself, I thought I’d throw the questions over to you guys!

#1: Is it possible to make a tenoning jig for the router table that is similar to one you might make for the table saw? For example, one on which you could clamp pieces vertically, and ride along the fence for reference. In my particular instance, I would like to make a sliding dovetail, and the protruding part would have to ride vertically along the fence.

#2: Is it possible to make a kind of miter fence or crosscut fence, using t-track or otherwise, to make tenons faster and cleaner than you might make on a table saw?

The Ultimate Router Table

Brian Boggs – angled tenon

Get the Most From Your Router Table

Audio

Favorite vises

Joshua

I am currently gearing up to build my 4th bench (I am a glutton for punishment) and I am curious to know if/ when Mike is going to build another one. I know the FWW crew seems to be in opposition to the leg vise, but recently Mike hinted at liking the benchcrafted hardware and possibly making a modified leg chop. I would love to hear more on this topic.

Quickfire questions from Discord:

Andreas

Any tips or suggestions on shop lighting? I am planning a new shop space and looking for a good solution.

John:

Offbeat skills to try in between projects for people who usually do flat work…. Steam vending, hot pipe bending, soon carving (or green woodwork in general), etc.

Chuck:

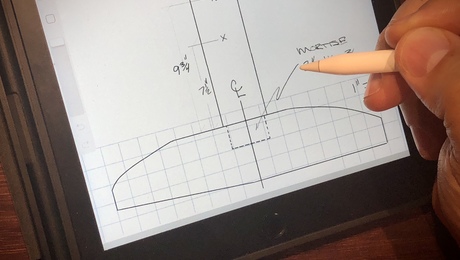

If Mike is still using an iPad for designing furniture I’d like to know what software he’s using.